All parts for clinker cooler

Cooler plates

Base plate

Cooler profiles

Drive Plates

Grate Plate

Lip Seal

Locking wedge

Retainer bracket movable

Slide Systems

Cooler Plates, Connector pieces, Crushing Rings for new generation coolers etc.

We also supply some wear parts of cement kiln, preheater and Calciner section as per customer’s requirements.

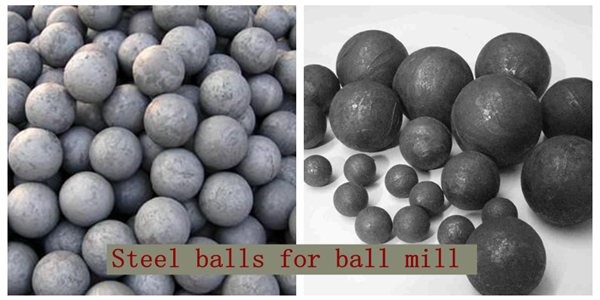

Changing impact conditions can cause conventional grinding media to either work harden or cause spalling – thus shortening working life, increasing downtime and increasing costs.

Our Group Industries has developed a whole series of alloys specifically suited to the different impact and abrasion conditions that can occur, such as low abrasion/high impact and high abrasion/low impact.

Balls Dimensions:15 , 17.5 , 20 , 25 , 30 , 35 , 40 , 50 , 60 , 70 , 80 , 90 , 100 , 125 mm

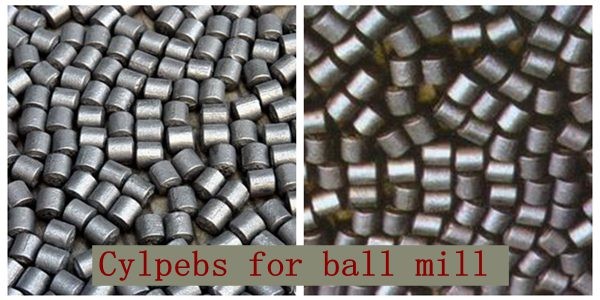

Cylpebses / Bulpebses Dimensions:

10x10, 12x12, 14x14, 16x16, 19x19, 22x22, 25x25, 30x30, 32x32, 25x45 mm

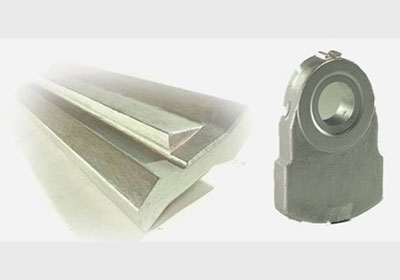

Whether using cone crushers, hammer crushers, impellor crushers or vertical shaft impact crushers; we can supply wear parts that offer significant cost benefits when compared to conventionally formulated and manufactured components.

Crushers

All important and major parts of crushers, like Impact Crusher EV:

-Rotor for Crusher

- Discs

- Grizzlies

- Jaws

- Blow Bars & accessories

Hammers

we supply different types of hammers suitable for your requirements.

- Clinker Crusher Hammers

- Hammers

- Hammers Bolts

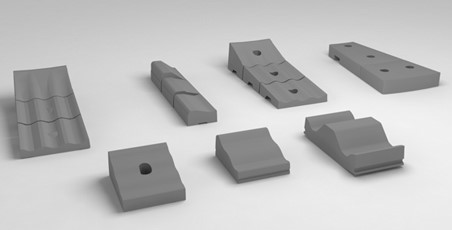

LINERS MADE TO LAST LONGER IN CEMENT MANUFACTURING

Our Group Industries manufacture Inlet discharge Head, First Chamber and Second Chamber Liners to provide optimum productivity and power consumption for all types of Tube Mill used in the Cement industry. Shell liners can be supplied in either bolted or boltless design, as per either DIN standard or Non DIN shell drilling pattern.