Anchoring Systems

we offer a complete line of metallic and ceramic anchors to secure monolithic installation. The proper selection and spacing of these anchors is an essential criteria to obtain the stability of lining.

Metallic Anchors

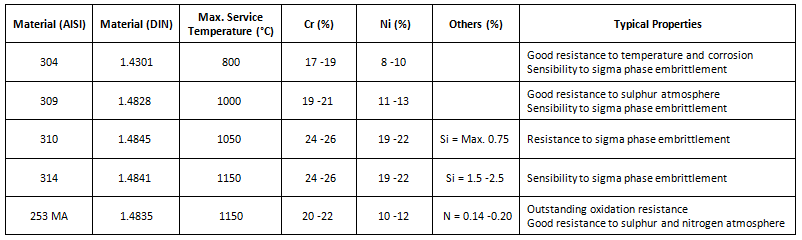

Metallic anchors are the most common anchoring devices used due to their low cost and easy installation. Metallic anchors are used when service temperature do not exceed 1100°C, at higher temperatures ceramic anchors are recommended. The thickness and dimension of metallic anchors depends on the type of refractory material, lining thickness and process conditions such as temperature and chemical environment. You can find information about commonly used heat resistant alloys below:

Choosing the right anchor alloy is critical. Considering the working condition in cement industry, we recommend using AISI 304, 310 and 253 MA alloys for anchoring. You can definitely contact with us for more professional advices in order to select the right anchor material based on your specific requirements.

CeramicAnchors

whenever there is a very high temperature in the furnace lining or a severe corrosive attack is to be expected, ceramic anchors are recommended. Ceramic anchors are placed in walls, roofs, arches and noses to provide support for the refractory mass. Our company makes various lengths of ceramic anchors based on andalusite which has an excellent thermal shock resistance. The brick shape, with its grooves and rises, provides excellent retention power over the monolithic lining.